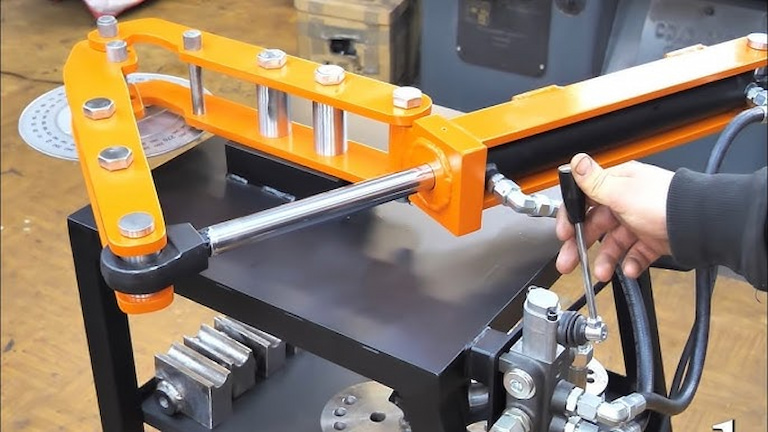

In the world of metalwork, a hydraulic pipe bender is a game-changer for anyone who needs to bend pipes accurately and efficiently. Whether you’re in the business of creating custom piping for automotive work, construction, or industrial use, hydraulic pipe benders provide a reliable and powerful solution for shaping pipes with precision. Unlike manual methods, hydraulic pipe benders take the strain out of bending and deliver consistent, repeatable results, even on tougher materials.

What is a Hydraulic Pipe Bender?

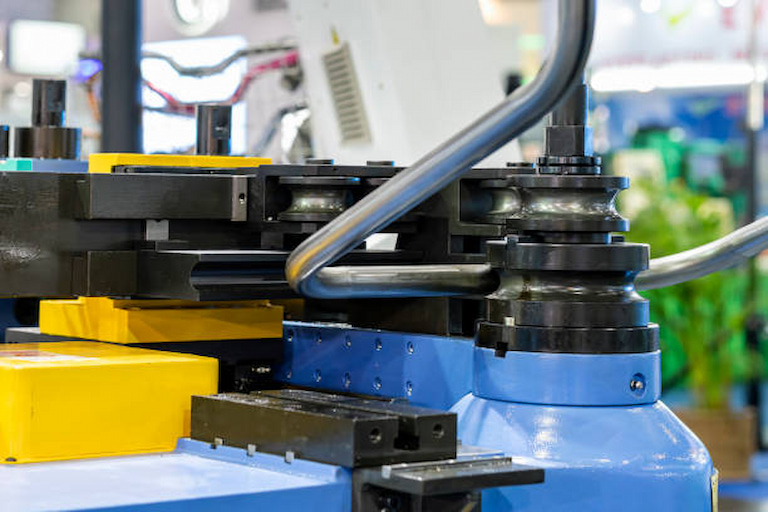

A hydraulic pipe bender is a machine used to bend pipes and tubing without causing damage to the material. These benders use hydraulic pressure to exert a controlled force on the pipe, allowing for smooth and accurate bends with minimal distortion. Designed to handle various metals like steel, stainless steel, and aluminium, hydraulic benders are essential for professionals who need reliable and accurate bends in their work.

The beauty of hydraulic pipe benders lies in their versatility. They can produce bends in different radii and angles, making them suitable for everything from simple bends to complex, multi-angle bends required in custom metalwork projects. With a hydraulic bender, achieving the right curve in heavy-duty pipes becomes manageable, saving both time and effort.

Why Choose a Hydraulic Pipe Bender?

Hydraulic pipe benders make metalwork easier, more accurate, and efficient. Here’s a closer look at why they’re so beneficial:

Precision and Control

Hydraulic pipe benders offer precise control over bends, ensuring each angle is accurate. In jobs like construction and automotive work, where exact angles are critical, this accuracy helps avoid errors that could compromise safety or functionality.

Effortless Operation

Hydraulic systems do the heavy lifting, so you don’t have to. By using controlled pressure, the machine takes on the physical strain of bending, making it easier on operators, especially for longer or more complex jobs.

Versatility Across Metals and Pipe Sizes

These benders handle a variety of metals, from mild steel to stainless steel and softer metals like copper. They’re also adaptable to different pipe sizes, meaning one tool can handle a wide range of tasks without requiring additional equipment.

Consistency and Reduced Material Waste

Hydraulic pipe benders are designed to deliver uniform bends every time, cutting down on material waste from mistakes and distortions. This consistency saves money on materials and helps create a clean, professional finish for any project.

Key Features of Hydraulic Pipe Benders

When choosing a hydraulic pipe bender, a few core features will determine its suitability for your needs:

Bending Capacity

The bending capacity is the maximum diameter and thickness the machine can bend. If you’re working with larger pipes, be sure to choose a model with sufficient capacity. For lighter jobs, a smaller bender may be more portable and easier to handle.

Ease of Operation

Some benders have simple lever controls, while others come with digital settings for more advanced precision. Consider your comfort level and the requirements of your projects when choosing the right type of control.

Portability and Space Requirements

Hydraulic pipe benders come in portable and fixed models. Portable benders are great for on-site jobs, offering flexibility, while fixed units are more robust and suitable for workshop environments. Assess your workspace to decide which suits you best.

Quality and Durability

Investing in a well-built, durable bender will pay off in the long run. Look for solid construction, high-grade hydraulics, and sturdy dies. Quality machines not only perform better but are safer to use under high pressure.

Popular Uses for Hydraulic Pipe Benders

Hydraulic pipe benders are commonly used across different fields for a variety of applications:

Automotive Fabrication

Hydraulic benders are ideal for custom automotive work, such as bending pipes for exhausts or roll cages. They allow precise bends needed to fit vehicle parts correctly and safely, meeting both performance and aesthetic standards.

Construction and Infrastructure Projects

In construction, hydraulic pipe benders make installing pipes for water, gas, or electrical conduits simpler and more accurate. Their precision reduces the likelihood of leaks and other issues, which is essential for long-term durability.

Industrial Manufacturing

For industrial applications, these benders handle large-diameter pipes and structural elements with ease. They provide reliable bending for heavy-duty materials, making them essential in manufacturing environments where safety and accuracy are critical.

Metal Art and Custom Fabrication

In custom metalwork and art, hydraulic pipe benders offer the control needed to create unique shapes and complex curves. Their versatility makes them a favourite tool among metal fabricators and artists alike.

Tips for Using a Hydraulic Pipe Bender

For safe and effective use, follow these tips to make the most of your hydraulic pipe bender:

Choose the Right Die

Using the correct die size helps prevent pipe crimping and distortion. Check the manufacturer’s guidelines for die selection to match the pipe’s diameter and material for a smooth bend.

Monitor Hydraulic Pressure

Maintaining the right pressure is key to getting accurate results and keeping the machine safe. Too much pressure can damage both the pipe and the machine, while too little may result in poor bends.

Secure the Pipe Properly

Make sure the pipe is clamped securely to avoid slipping or misalignment. Most benders have adjustable clamps or vices that keep the pipe in place during the bending process.

Regular Equipment Maintenance

Regularly inspecting hoses, dies, and hydraulic components extends the life of the bender and ensures it remains safe to use. Maintenance is essential to keep the tool performing at its best, especially under heavy usage.

Final Thoughts

A hydraulic pipe bender is an excellent investment for professionals in metal fabrication, construction, and automotive industries. Its precision, power, and ease of use make it invaluable for anyone needing consistent and accurate pipe bending. With the right hydraulic pipe bender, you’ll be able to tackle complex projects with confidence, delivering high-quality results that meet industry standards. By considering features like capacity, durability, and portability, you’ll find a machine that fits your needs and enhances your productivity on every project.