If you’ve ever worked a job where the primary duty was material handling, whether retail, machinery or anything similar, you know how strenuous the process can be, and how it’s a demotivator at work. Luckily, there is material handling equipment whose use is straightforward. You use it to simplify the job, thereby making it easier and making the workplace more productive. Furthermore, it makes everyone happier and more motivated at work. No one likes to do a difficult job that can lead to an injury. But everyone enjoys using the machinery and constructions that make all the difference.

With that in mind, we decided to write this article about some equipment types that I consider vital for any business, especially the ones that come in handy for particularly tricky situations. There are many other guides, but I decided to focus on the three types I see as paramount. Specifically, I will focus on lifting and trolley equipment, drum equipment, and waste handling equipment. All three can be a game-changer for the organisation and function of your business.

Lifting Equipment and Trolleys

These are the most common and most helpful type of equipment for material handling. They’re simple to use with a push and pull mechanism, but certain types are better than others. That being said, always consider several factors to make sure you get the right one for you.

Material

Before you even go through the available types, you need to define the characteristics of your workplace. First and foremost, figure out what materials and goods you’ll work with. More specifically, the weight, the dimensions, and peculiarities. Moreover, if they are fragile, you want to get equipment that’s extra stable.

Space and Organisation

Afterward, you need to see what type of space you’ll be working in. For example, is your facility spacious with plenty of room, or is it small and full to the brim? Depending on the size or the lack thereof, you’ll need to get a smaller one so that you can maneuver it around. Lastly, you need to analyse the type of shelving in your business.

Technical Features

As the purpose of lifting material lifting equipment and trolleys is to carry and move things around, the loading capacity is a crucial consideration. Further, it’s also one of the distinguishing factors between lifting equipment like pallet lifters and forks from trolleys. Trolleys can carry a maximum of around 500 kilograms, depending on their build and material. However, pallet lifters and forks can easily lift even 2500 kilograms. If you work with lighter goods and materials, then a trolley will do the job. Otherwise, lifting equipment is necessary.

Another distinguishing quality is that trolleys can only be loaded and pushed. You can’t lift anything with them if you want to reach something up on a shelf. But you can do this with pallet lifters and forks. However, even lifters and forks are somewhat limited, as most of them come with a certain maximum lifting height. Additionally, there is a difference between manual and electric models. Some of them need to be lifted by pressing downwards on the handle and pushed to move, while others are completely electric, and you need to press a button to do both of these things. On the downside, electric models have one major drawback – they require regular maintenance as the parts can be damaged over time.

Types and Extra Features

Depending on your line of work, you might want to get specialized material handling equipment. If you work with plenty of materials that need to be moved quickly, you can get an extra-long pallet lifter. Or, if you work in the food, pharmaceutical, or chemical industry, you can get one made with corrosion-resistant metal, like stainless or galvanised steel.

If you want to maximise the working space, you can get a trolley with multiple levels. But if you’re moving something that is extra-long, some trolleys come with an extra platform size. Finally, if you need to move something up stairs or ramps, there are heavy-duty appliance trolleys. All you need to do is put the product on the base plate, tilt it, and you’re good to go.

Drum Equipment

As there are many types of materials you have to move, your materials handling equipment must also adapt. If, for instance, you work with liquids, you know how heavy and impossible it is to lift a 40-gallon drum. You can’t carry the drum without it moving back and forth with your hands, and there aren’t any ways to lift it using the handles. It’s also incredibly easy to get hurt should it fall on your feet or legs. To avoid this burdensome task, you can put the drum on a regular pallet lifter or roll it down, but there is a better way – specialised drum handling equipment, which mainly comes in two types.

The first type is the electric drum lifter and rotator, and the second option is the manual one. With both options, the first thing you should pay attention to is the load capacity. Then, you need to check the type and the dimensions of the drums they can carry. If your goal is to carry drums long distances and lift them high to put them on shelves, it’s best if you get an electric drum lifter and rotator. If you need to move them and put them down, then a manual carry and rotator will do the job.

Waste Handling Equipment

The handling and disposal of trash is never easy, and no one wants to do it. It’s always smelly, and even looking at it can be sometimes unbearable. As a result, equipment that is designed to do away with it can be of great help. Luckily, there are three main types of waste handling equipment that you can get.

If you work with non-corrosive regular materials, you can get a plastic bin. This bin can come in the standard wheelie form that stands upright, and you tilt to move it. But, if you need to move heavier garbage, you can get a waste bin trolley or dumpster with wheels on it.

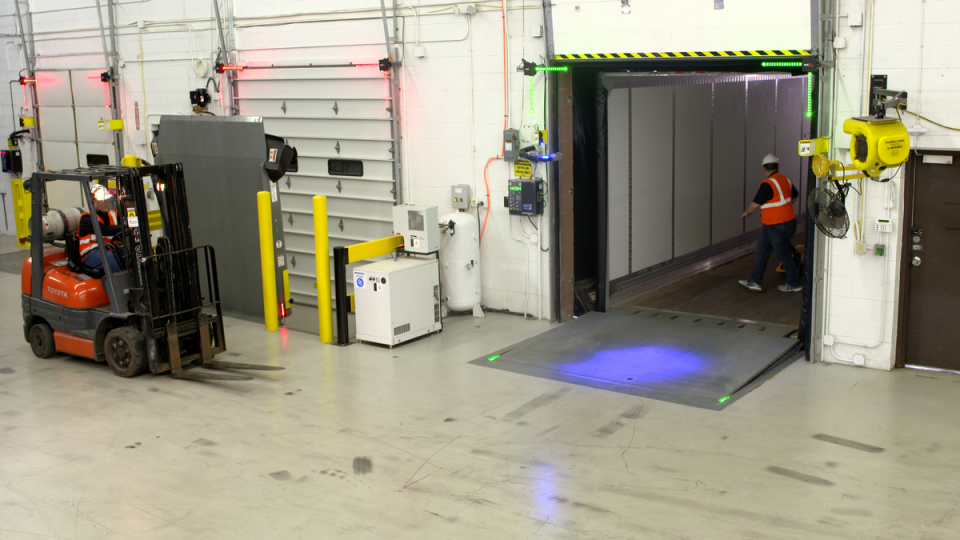

If, however, you work with corrosive and heavy-duty materials, you can get a steel one that is built to withstand both. Some of these can also be moved with forklifts, which you then open at the bottom to dispose of everything. An example of such is a drop bottom pin.