With life so advanced nowadays thanks to technology, it’s not surprising an average person has a number of electronics at his or her disposal. There are those that fit in a pocket, a bag, a purse, bigger ones, smaller ones, sturdy ones and then there are also those more prone to damages. Of course you don’t imagine you’d have to face with either frequently repairing or replacing them altogether once you buy them, which is why you need to take proper care of them. More so when your profession demands it, be it photography, music, conducting electrical and equipment tests or scientific work.

Industrial Equipment

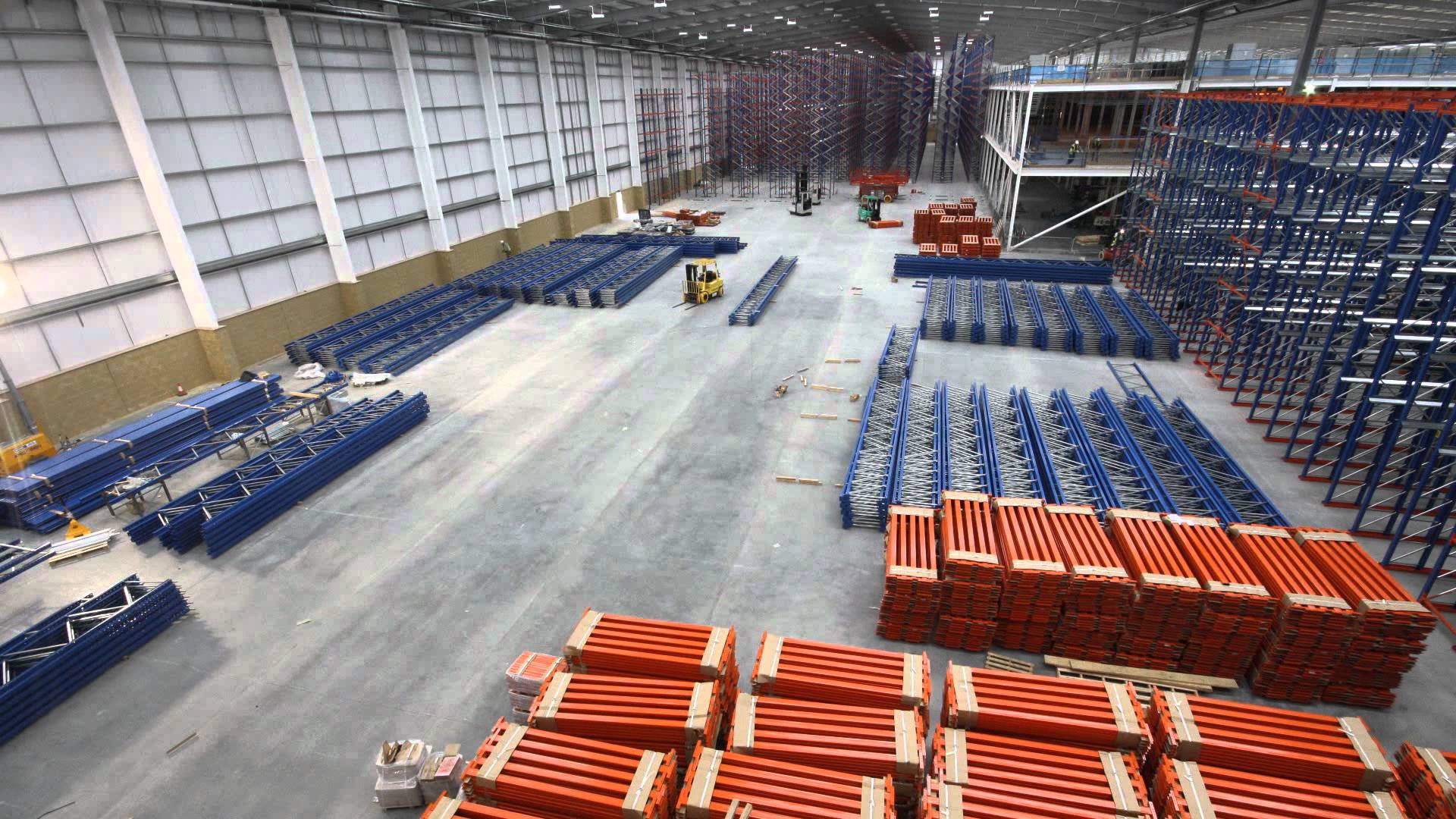

3 Smart Steps for a Warehouse Success

My favourite mantra to live by in days when I have tons of work to do? – Don’t work hard, work smart. It doesn’t matter how much time you spend doing something, if you aren’t focused on doing it right, it will probably take more time than it has to. That rule applies to many other things in life – just because you own a big warehouse, that shouldn’t mean that you shouldn’t organize it properly to maximize the efficiency of your business.

By having a well organized warehouse management system, you reduce the time your customers wait for their products to be shipped, you lift a huge weight off the shoulders of your employees, and you can keep better track of all the products you own and organize them properly. These are just some of the many benefits that come with operating a smartly organized warehouse. However, in order to make it happen, you have to go through a few steps first.

Step 1: Planning and Organizing

Before you start operating a warehouse, you need to plan and organize beforehand. How many products will you store? How big will the products be? Will you be using vehicles? These are some of the questions you should answer before you go any further. The purpose of the warehouse should be to streamline your business. A well organized warehouse should increase the productivity of your employers and help you keep track of their performance, which will give you direct visibility of the efficiency of your workforce. If you are unsure about any of this, consider contacting a company that offers warehouse storage solutions.

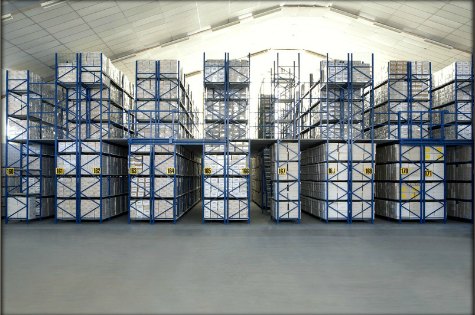

Step 2: Consider the Racking System

As I previously stated, a big warehouse doesn’t mean an efficient warehouse. You can save space in many ways, but the most notable one is by utilizing vertical storage capacities instead of floor space. There are many types of racks, like pallet racks, that can be placed as high as the ceiling. Pallet racks are also made from high quality materials, which makes them safe. The safety of your employees and your products should be a top priority for you. Furthermore, they are very affordable, which makes them the top choice when it comes to picking warehouse storage solutions for your business.

Step 3: Evaluation and Flexibility

Errors are bound to happen in warehouse management, so you need to have a team prepared to adapt to the changes in the process. The demands of vendors and customers will vary, which will drive the shipping process. If a problem occurs, the warehouse processes should be reassessed to determine whether a change in procedure will correct the problem. Being flexible is crucial in order to meet the demands on the market.

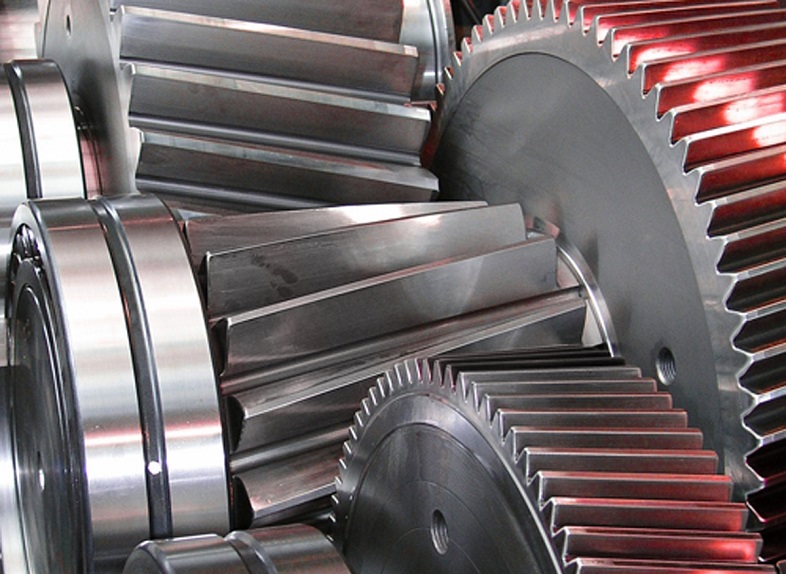

A Guide to Step Up Your Knowledge on Planetary Gearboxes

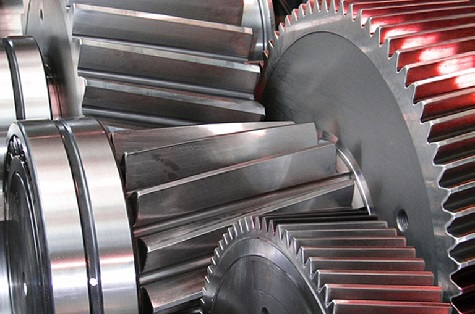

The most basic function of a planetary gearbox set is to change the revving speed of an engine while maximizing its output torque and any gear ratio. The gearbox, together with the engine is the driving mechanism of the car. It needs to be properly functional and kept in a good state to maintain the car’s reliability and avoid breakdowns.

A high quality planetary gearbox set offers low backlash, high torsional stiffness and very high levels of efficiency, which also makes them great for industrial automation applications. They are also suitable for working in high torque applications where feedback is necessary. Planetary gearboxes are constructed from three gears: planet gears, ring gear and a sun gear.

Step-by-step guide: Getting Familiar With Multimeters

If you are looking for a tool that will measure the continuity, voltage, capacitance, resistance, current, and temperature, then look no further than a multimeter. While not all models will do the same thing, they generally work the same. There are a few things to look for when you are looking for multimeters for sale which includes necessities, nice extras, and things that you probably won’t use that much. Below we will be going over what you should look for in a multimeter and how you can get familiar with the device so you can use it more easily.

A Good Home Lighting Design Can Really Define Your Interior

Any aspect of decorating your home is important. From the style of the furniture to the smallest pieces of décor. In all this arrangement, lighting takes a very important role. The type and design of lighting can either make or break the entire atmosphere in your living area, so you need to put more effort in the selection of it. The right type of home lighting design should be both efficient and effective. Efficient, so you can use the least amount of energy but still get the effect you want and effective so it can crate a certain mood, provide security or illumination fro a specific task.

Consider the natural light

Before you dive into the wide range of home lighting design options available, consider the type and amount of natural light that reaches the room. Main living areas, including the kitchen, should be face south-facing so that natural can keep the space bright and warm during the larger part of the day.

Make a plan

A good lighting plan should take into account any aspect of the room. A well-designed lighting plan will have a huge impact on the finished look of the room. You can start your lighting scheme with the following simple questions:

- What will this space be used for?

- Will there be furniture pieces, artwork, and architectural features?

- Who will be using the room?

- At what period of the day will it be used the most?

- From what direction does natural light enter?

Once you answer these questions, you can start making the plan. Consider the placement of the light fixtures, light switches and the major furniture items. When you are done with the plan, you can start looking for the right home lighting design that will complement your home interior.

Living room

Without any doubt, this is the most frequently used room in the home. When it comes to lighting, more and more people today are choosing to provide light for this room through a combination of table or floor lamp along with downlights. Chandeliers are also a preferred choice since for many people, the living room wouldn’t feel complete without one.

Bedroom

You really shouldn’t bother too much with the lighting of this room in the since two table lamps placed on each side of the bed are enough to do the job. Installing light switches on the either side of the bed is also a good idea since this will give you the ability to control your light without the need of standing out of bed.

Bathroom

Bathrooms allow a lot of creativity when it comes to lighting. Small or big, there are always those things you can accent, and include various options so that you can change the ammosphere as you desire. If you want to add some background lighting consider recessed downlights or you can use a light above the mirror.

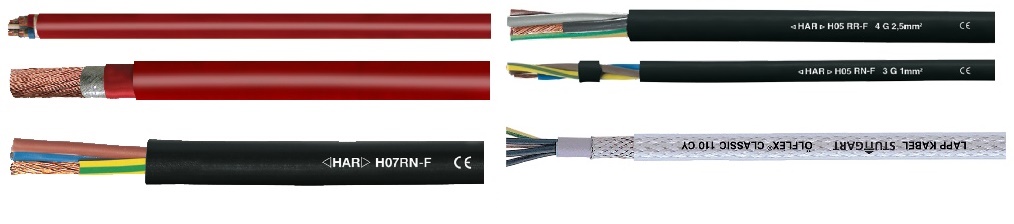

High Temperature Cables: Reduce Unnecessary Replacements and Avoid Downtime

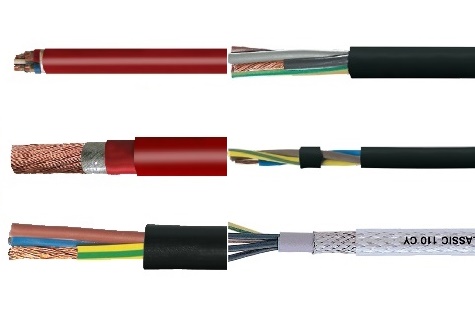

In general, cables are under immense temperature pressure because of the energy and heat that the flow of current through them emits. In order for extreme fire chaos to be avoided, the first thing to be taken into consideration is the choice of heat resistant materials for building those cables. There are various materials that can be used to provide insulation from high temperatures and make the cables useful.

High temperature cables serve to withstand extreme temperature changes that come down to extremely strong cold and hot influences. They’re designed with a special core and a layer of insulation made from a specific type of material depending on the purpose of use of the cable. The main areas where high temperature cables are used include power stations, iron works, foundries and factories for cement, ceramic and glass. They’re also used in aircraft construction and shipbuilding, brickworks and design of kitchen appliances – basically everywhere where constant flow of current is included and the result may be a fire caused by an overheated use of the device.

For these high temperature cables various types of materials are used in order to offer high functionality and safety. Among the most commonly used ones are silicone, rubber and fluorinated polymeric materials. The thing that distinguishes all of them is the specific area of application of each type: besides the aforementioned areas of use, heat resistant cables are also used in lamps and lamp holders in heat and air-conditioning systems and leakage monitoring systems. Each type of cable has its own specifics.

Silicone cables

In applications where the cable insulation is subjected to dangerous and extremely high temperature fluctuations, silicone-rubber insulated cables are used. These cables can withstand temperatures of up to +220 degrees Celsius, but only on short periods. The lower range can go down to -60 degrees Celsius thanks to the weathering resistance these cables have, which is excellent. These are mainly used for applications in iron and steel works since they are also halogen-free.

Fluorinated polymeric cables

Also known as teflon cables, these are generally used in applications such as control cabinets that are subjected to high temperatures, like kitchen fitments, measuring appliances, heaters, brick-works and similar. However, these aren’t as heat resistant as the silicone-rubber insulated ones; their temperature range is from 100 degrees Celsius up to 205 or 230 degrees Celsius in some cases but for very short periods.

Besides these most popular types of cables and most frequently used ones, the market also offers variations of them with even more great features for an even higher degree of protection. With the addition of other materials like nickel, copper and steel, the cables gain even more strength and resistance features.

Industrial Racking: Choosing the Right Type is the First Step to Better Productivity

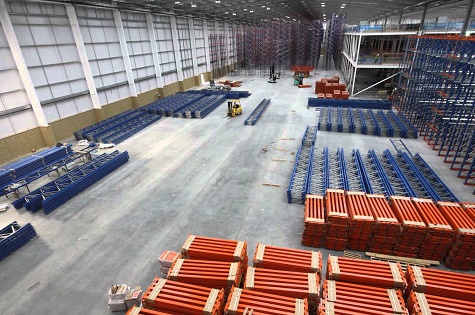

When looking for a way to maximize the storage space in your warehouse, or other storage setting facility, the right way to do it is racking. Racking will benefit you in many ways – it will increase safety, productivity, it will free up more space which will result in being able to place more products. On top of that, industrial racking is simple, safe and very efficient.

When looking to construct a pallet racking system, there are some things you need to take into account. You want to buy from a reputable and reliable company that has experience in industrial racking. These companies supply durable, high quality and affordable pallet racks that ensure you will optimize your storing facilities to fit your needs. The pallet racks are made of high quality materials that are especially designed to withhold heavy items and be stable at the same time. Let’s take a look at what else a quality pallet racking system will provide you with.

Safety

This is a top priority. For this reason, you want to buy from a reputable shop that has much experience in this particular industry. You don’t want a heavy crate to fall off and injure your employees or yourself. A quality pallet rack with the right capacity will prevent this. Plan out your racking carefully to avoid these mishaps. Also, make sure your employees follow all safety measures.

Efficiency

Keeping track of your products is important. With proper racking, you will know the quantity of a certain product you have left in your warehouse. Moreover, your employees will have an easier time locating and shipping products. Pallet racks can usually be accessed from both sides, so this makes them super convenient.

Space

This is the biggest advantage of pallet racking systems. You need to take into consideration how much free space you have in your storage facility, that goes for both floor space and height. If you are limited with floor space but your warehouse is vertically large, no problem, add racks on top of each other. Having enough space for forklifts to move around can be a game changer as being able to store and bring down products with a forklift increases productivity.

If you have any questions, simply contact a company that specializes in industrial racking, and come up with a plan to maximize your storage facilities’ capacity and effectiveness. High quality racks will last you for many years and your business will run more smoothly and be more profitable.

PM-10 Energy Meter Plug: Comprehensive Device, Plus Easy to Use

If you are someone who is looking for an efficient plug in energy meter, look no further than the PM-10 plug in power and energy meter. This piece of technology is a comprehensive plug in power monitoring device which is known for being easy to use. The standard design has been designed to be able to plug into a standard 10A power outlet from where it can instantly measure and monitor a wide range of electrical parameters. Some of the things the PM-10 energy meter plug can display includes real power consumption, power factor, voltage, supplied power, current, and much more. If you wish to know more about what the PM-10 can do then keep reading below.

This nifty little device can measure a whole range of electrical parameters that are related to any kind of plugged in device or appliance. As stated above some of the things that the PM-10 can display includes real power consumption, power factor, energy consumption, supplied apparent power, frequency, and a lot more. Another great feature that you get with the PM-10 energy meter plug is that you can input the cost per kilowatt-hour of electricity. By inputting the cost per kilowatt-hour you can easily and effectively measure the cost of any plugged in device or appliance. This same feature can also easily measure that device or appliances greenhouse gas emissions.

One of the well known features about the PM-10 is no doubt the back lit LCD screen it comes with. The LCD screen that comes on the front of the PM-10 can display a number of things all at one time. More than that there are also different screen settings for greenhouse gas emissions, cost, energies, meter mode and more. The front of the PM-10 energy meter plug has all the functions you need in one spot. There are 3 soft touch buttons that control modes, settings and functions. There is also a receptacle set in the front which is able to accept a variety of different plugs from different countries. There is a whole range of features that you might find useful all of which we will go over.

There are so many different features that come with the PM-10 energy meter plug which includes it being user friendly, light weight, and compact. It is simple and plugs into any 10A power outlet, it comes with a user friendly interface, measures energy consumption as well as running costs, measures both active and apparent powers, can monitor appliances up to 2500W, comes with a warranty and great customer support, can measure more than one thing at one time, accepts a range of plugs, measures power factor and comes with calibration protocol.

Ls Frame: A Simple Step to Say Yes to Added Safety and Functionality

Companies in which managing big warehouses and a very large product palette is the centre activity know it best: organization is key and the main weak spot in their efficiency and speed of work. If there’s just a slight slow-down in the entire work procedure, the effect is instantly felt on the monthly income: it’s lower, and that doesn’t make the managers, nor the stockholders happy. Not to mention the situations in which a product gets damaged because of improper placement or an inconvenient location in the warehouse; that’s loss from the very start. And finally, let’s not forget the safety of the workers whose main job is to manage the product palette in warehouses; one wrong maneuver in managing the situation can be a serious health hazard which eventually will fall on your account.

While the solution is obvious, the details are a little more specific and require more attention. Normally, you’d solve the organization problem in your warehouse by installing a shelving system with a sturdy construction and of a considerable quality – one that would increase the level of efficiency in your work. And the detail to not neglect here is the use of an Ls frame. While a Ls frame is nothing largely different than other types of frames in shelving systems, it definitely is the type of shelf worth considering. Here are a few points to think about.

What is a Ls frame?

This type of framework serves the same purpose as other types of frames in the shelving business: to support rails and racks. You can find them made of various materials, but mostly they’ll be made of stainless steel, aluminium or iron – as the hardest and sturdiest of metals for supporting a large amount of load. Some of them are even powder-coated so they can offer more visibility which contributes largely to the level of safety of workers who manage the shelves.

Types of shelving systems that can use Ls frames

There are various types of racks that can use Ls framing, such are:

- Open frame racks – these have no doors and no sides. These shelving systems rely completely on the support of the frames and the strength of the rack surface to withstand heavy loads. They are mainly used where physical security of the load placed on the racks isn’t a priority and airflow doesn’t need to be controlled that much.

- Rack enclosures – rack enclosures are very much like rack cabinets with doors, removable side panels and vertical mounting rails.

- Wall-mount racks – as their name suggests, these are attached on the wall. Ls frames can be used for these racks, but have in mind that the whole construction needs to withstand on the wall and support the load placed on them. Because of that reason, these systems aren’t designed to hold very heavy loads, despite the strength of the frame.

The Multiplicity of Spiral Bevel Gearboxes Explained

There are many reasons why one could go on forever touting the benefits of spiral bevel gearboxes, the hardest thing being deciding which ones to ponder the most. In this article, we’ll try not to lose sight of the key facts that need to be highlighted as to gain firm basic knowledge about this old-fashioned, yet forever revolutionary invention. In addition, we’ll present our own suggestion in the light of the listed facts.

The proper function of a bevel gearbox is based upon a method called Klingelnberg palloidspiral gearing. The spiral tooth is the essential tool that makes the transmission of the high torques possible as it creates the contact. The material used for the making of the bevel gear sets is alloy steel of high quality and they are hardened afterwards so that maximum efficiency can be reached.

This reliable and quite tangible technology is implemented in many industries and there is a countless number of manufacturers offering their gearboxes. However, since nothing beat German technology – they speak the language of quality, efficiency and affordability combined, our suggestion for industries that are looking forward to their expansion is to opt for nothing less than Vogel spiral bevel gearbox.

Apart form being a German company that is offering only high quality products in the field of gearbox manufacturing, Vogel’s standpoint is developing energy-saving instruments, the efficiency of which won’t compromise the quality. The Vogel spiral works with the highest allowed limit in regard to thermal performance. It features friction-locked fit that is positioned between the bevel gear and the shaft.

Space and weigh efficiency are yet additional benefits of the sturdy, compact and rigid design. The motor of this gearbox is mounted by using lantern and coupling. Their main purpose in the industrial applications is increasing economic use when it comes to daunting industrial applications. This brand is well recognized due to their success in meeting special requirements: high speed and compatibility with various applications.

The most important thing that professionals always check is whether the clamping sleeve, the shaft and the bore are not covered with residual dirt. On the coupling there is a sticker on which one can find specification that state the level of the recommended torque.

It should go without saying that a Vogel Spiral Gearbox can save any industry money and time, it is the type of technology that can take the efficiency on a higher level all while empowering another device.

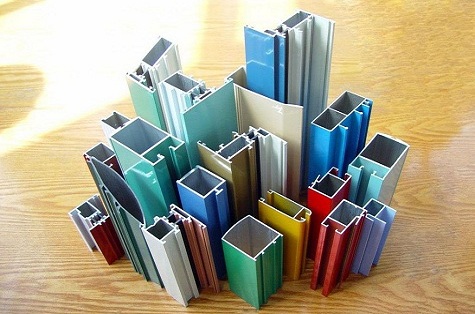

3 Important Processes In Aluminium Fabrication

Aluminium is no doubt one of the most commonly used materials in the world. It is used in so many industries for so many different applications as to create products that are an integral part of our everyday lives. Most people who work with metals already know that the process of aluminium fabrication if of utmost importance to so many manufacturers in various industries and it has much more applications and uses compared to the fabrication of other metals. It is also fabricated in so many different ways to produce all different things. Below we will be going over three important steps in the aluminium fabrication process that you should know about in order to understand the process completely.

Extrusion

This is an important step in the fabrication process as it puts less stress on the material compared to other methods. Other fabrication methods may leave you with a brittle finished product, whereas this method helps keep aluminium strong. To go a little more in depth it all starts with the design which is where the extrusion takes shape. It involves preheating the aluminium under a high pressure which is then fed through a die. This is the opening that corresponds to the cross section of the extrusion. Once it has gone through this process it is left to cool, once it has cooled it is then taken to be used.

Cutting & Joining

Aluminium can be cut in many different ways depending on the shape you are trying to achieve. It can be cut using a saw and laser for basic shapes or a water jet to achieve more intricate shapes. The water jet cutting method seems to be preferred by those who work with aluminium simply because there is no heat and that means there is no risk of distorting the metal. The most common way of joining aluminium together is welding. There is a layer of corrosion resistance on aluminium which is caused by the tough oxide layer on the outside. This oxide layer has a higher melting point than the aluminium itself and needs to be removed before welding. Once this has been removed, aluminium has a low melting point so constant care must be taken to not overheat it during the fabrication process.

Deep Drawing

This is a very common fabrication process and it is used to make one of the most common products – cans. The entire process involves using extremely high pressure to push a sheet of soft aluminium through a female draw cavity. This takes many steps and many stages where a lot of lubrication is required to get to the finished result. The most common types of aluminium used in this process are 3003, 5052, and 5005. The reason this is such an important part of the process is because it gives you a seamless product and end result. The process actually curls the aluminium and you are left with something that resembles a cup. This is a process that is used all over the world to give you an everyday item like a can.