Contents

Metal has been the core material when it comes to making sturdy machinery as well as long-lasting solutions in construction and many other industries. From shelving units to gigantic steel structures, fasteners are made to hold things together. A fastener has been long produced before there were machines made of metal.

The first-ever screws were made of wood in the 1700s. Although even before the 1700s there were screws being used, those were handmade, meaning they adhered to no standard.

By the 1800s, various fastener designs were made with the majority of them being made of metal. During the industrial revolution, there was a large number of bolts and screws made in such a small period of time, and it’s astounding how consistent and precisely they were made. It wasn’t until 1841 that a standard was introduced, though. Later on, in the 20th century, various tools were introduced to help make installing a fastener easier.

Which Fastener to Use

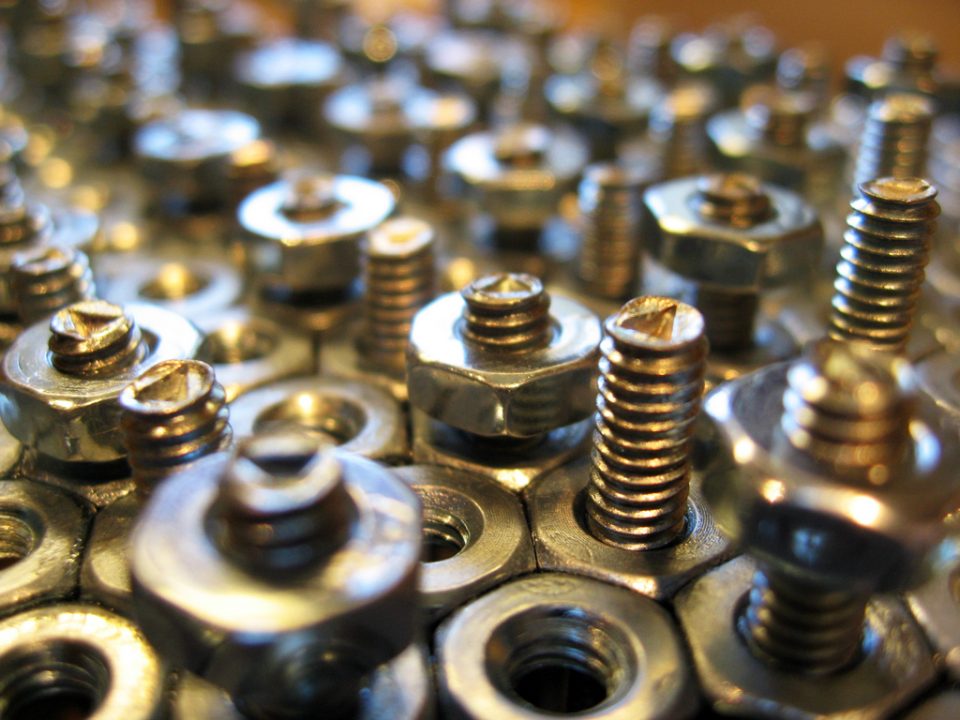

Screws

For a lot of people, a fastener reminds them of a screw as they are the most versatile. Screws are one of the most well-regarded fasteners since they have a threaded shaft that allows them to have durable holding power. They do not need anything to keep them in place. Usually, you just make a hole with a drill, and that’s about it. There are various types of screws nowadays, such as drywall, deck, masonry, machine screws, as well as wood, MDF, and sheet metal screws.

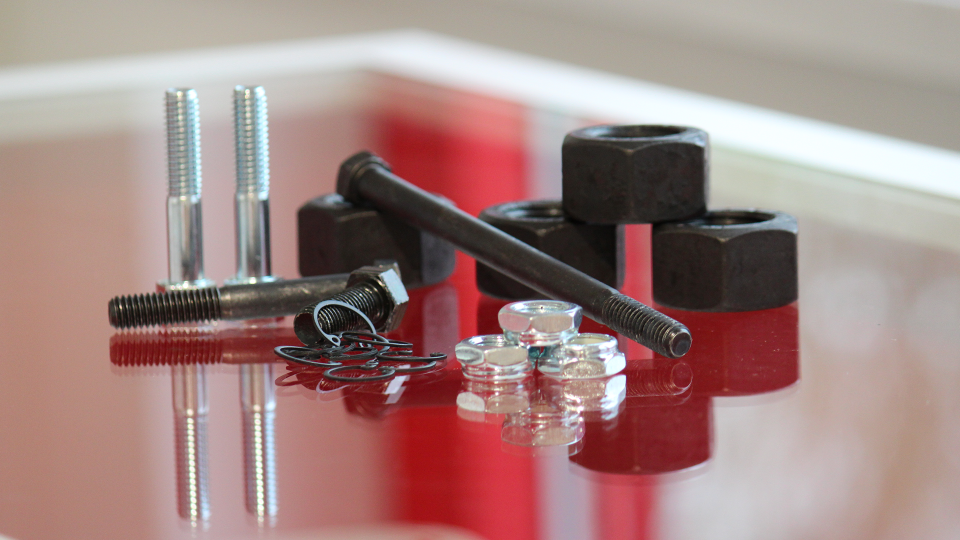

Bolts

Unlike screws, bolts are the type of fasteners that do require additional hardware to be installed. The bolt is inserted through two parts which it then joins thanks to the nut. You need a pre-drilled hole for bolts, as well as a hand or a power tool to fasten them. The most common types of bolts are plow bolts, Allen bolts, carriage and flange bolts, and others such as head-head and square-head bolts. You also have different types of nuts, such as lock, hex, coupling and flange nuts as well as wheel, square, and slotted nuts.

Nails

If you want a fastener that has been used since ancient times, and you want to use it in household applications, then a nail is what you need. Nails don’t offer a great deal of holding power since they don’t have thrashing, but that’s why they have great shear strength.

Anchors

An anchor fastener is one that resembles the function of a boat anchor. These fasteners for sale are bought because they can embed themselves into the material they’re being driven through. They are used mainly to connect an item to a material such as concrete or drywall. You can find anchors as screw anchors, hollow wall, drive and sleeve anchors, as well as externally threaded, internally threaded and masonry screw and pin anchors.

Rivets

If you want to create a permanent joint between two objects, then you should use a rivet. Rivets have a cylindrical shaft that has a tail on one end and a head on the other. To install a rivet, you need to use a unique tool that expands the tail of the rivet in order to secure it in place. A rivet is a durable fastener that is available in five different variations. These include blind, drive, and split rivets, together with semi-tubular and solid rivets.

Staples

Although not as commonly used as bolts or screws, staples are frequently used in construction projects. The unique design of staples allows you to bridge materials. The crown of a staple also makes for a bigger surface area which is a good thing if you’re working with thin materials. Staples can be installed and removed quite easily and quickly, and they can be loosened easily too. You can insert staples through a material with the use of a staple gun. Staples can even be used to fasten small cables, such as the one for your TV or phone.

Washers

A washer may not be a fastener on its own, but it helps in distributing a fastener’s load more evenly. A washer is essentially a flat disc that has an opening in the centre and although small, it can help distribute a lot of weight. There are different types of washers too, such as fender washers, lock washers, flat washers, finishing cup and lock washers.

Conclusion

In the world of megastructures and machinery used to build other machines, the need for a fastener in every corner is more than necessary – it’s mandatory. But this doesn’t mean it’s easy picking the right type of fastener for your application or build. You have to be wary of what your build needs and compare that to the capabilities of a certain type of fastener. If the two match then you got yourself the right fastener and one that will keep your build running for a long time.